Avionics Technician – Common Tools Used – A Guide to Aircraft Electronics

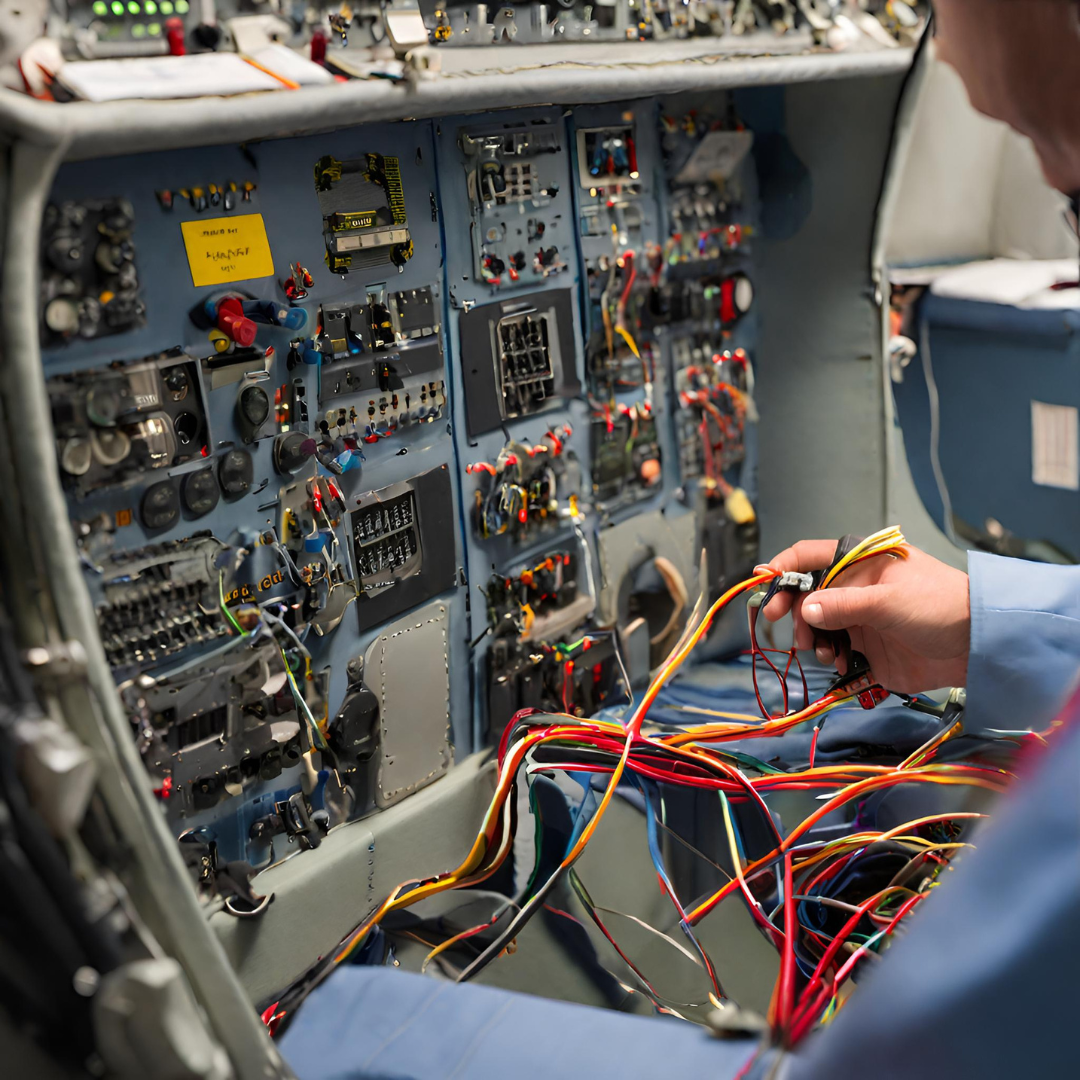

To properly maintain the electrical and electronic systems of an aircraft it is crucial to have a specific set of tools that prioritize precision and safety. These avionics tools play a role in ensuring the airworthiness of modern aircraft be it small general aviation planes or large commercial jets.

At their core there are always some hand tools required regardless of the aircraft being worked on. Some examples include:

- Screwdrivers: Phillips, flathead and Torx screwdrivers in sizes are indispensable when working with avionics components.

- Pliers: Needle nose pliers, diagonal cutters and slip joint pliers prove helpful for gripping wires securing components and cutting.

- Sockets and wrenches: For most avionics tasks having a ¼ inch drive ratchet and socket set is absolutely necessary. Additionally specialized sockets for avionics components may also be required.

Beyond these tools lie a range of specialized instruments that avionics technicians rely on for specific tasks. Some commonly used ones include:

- Multimeter: This versatile tool measures voltage, current and resistance—making it invaluable for diagnosing issues.

- Wire strippers and crimpers: These tools are essential, for preparing and connecting wires to avionics components.

- Soldering iron: Indispensable when it comes to repairing or modifying circuit boards.

- Vacuum desoldering station: This handy device safely removes components from circuit boards by suctioning up melted solder.

- Oscilloscope: An indispensable tool for analyzing signals and troubleshooting complex circuits.

Test equipment also plays a role in maintaining avionics systems. The following types are commonly used:

- Aircraft transponders: These devices help identify the aircraft to air traffic control.

- Radio testers: Used to verify the functionality of communication and navigation radios.

- Flight instrument test equipment: Specifically designed for testing flight instruments like altimeters and airspeed indicators.

When selecting avionics tools it is vital to prioritize quality and safety. Here are some key considerations:

- High quality materials: Opt for tools made from non-conductive materials that won’t damage sensitive electronics.

- Proper insulation: Ensure that the tools provide protection against electrical shocks for technicians.

- Regular maintenance: It is important to regularly inspect tools, for any signs of damage or wear.

By using the tools and following safety protocols avionics technicians contribute to ensuring safe skies for everyone. Additionally, manufacturers often offer packaged toolkits tailored specifically for avionics work, which can be a convenient option.

To ensure safety and efficiency it is crucial for avionics technicians to receive training in the utilization of avionics tools. Additionally, they must adhere to all regulations set forth by the Federal Aviation Administration (FAA) while performing aircraft maintenance. By adhering to these guidelines and utilizing tools avionics technicians contribute significantly to maintaining the safety and dependability of air travel.