Structures Technician – Rivets – A Guide to Aircraft Structures

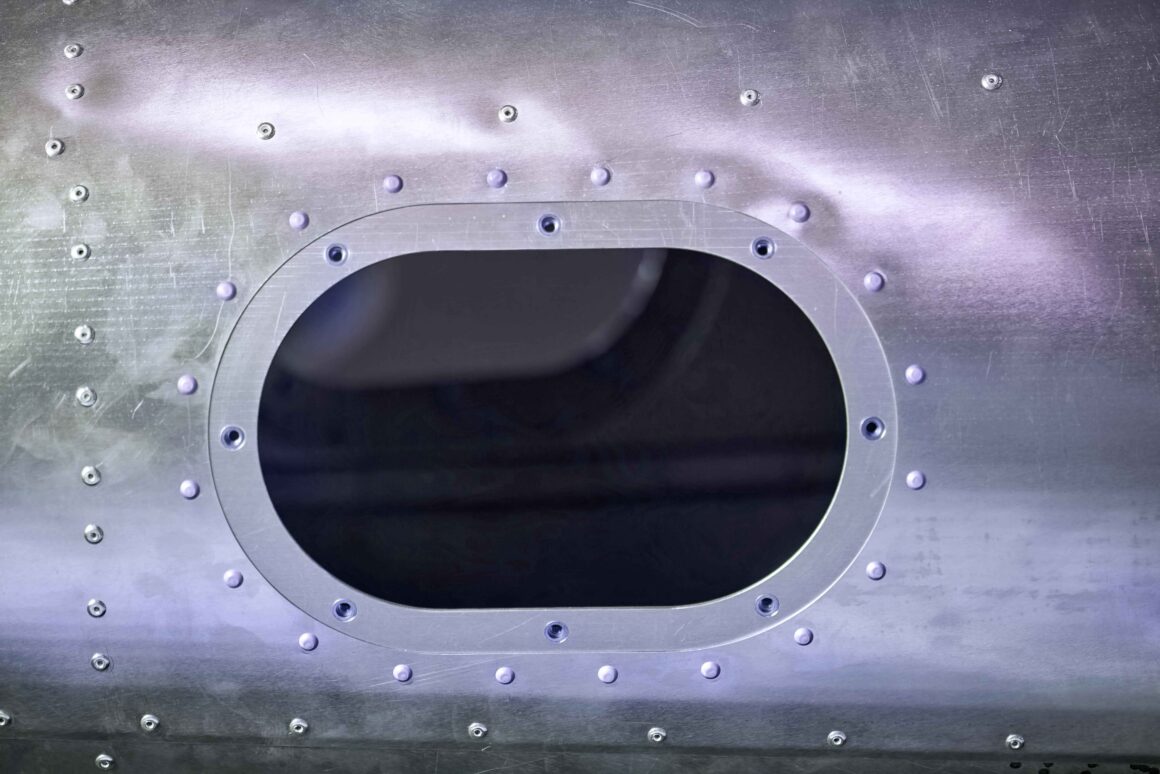

Aircraft structure technicians have the responsibility of maintaining and repairing various components of aircraft, such as fuselages, wings, and control surfaces. One crucial skill they possess is the utilization of rivets and blind rivets.

Rivets:

Rivets are cylindrical fasteners that permanently join two or more pieces of metal together. They are typically installed using either a rivet gun or a squeezer. Solid shank rivets are commonly employed in aircraft construction. These consist of a shank inserted through a hole in the metal pieces and then hammered or squeezed to create a head on the opposite side.

Blind Rivets:

Blind rivets are specifically designed to be installed from one side of a joint without requiring access to the side. This makes them particularly useful in situations where access is limited, such as within aircraft wings or fuselages. Blind rivets come in styles, but the most prevalent type is known as pop rivet. Pop rivets feature a shank that is pulled through the hole in the joint and then crimped to form a head on the opposite side.

Choosing the Appropriate Rivet:

The selection of a type of rivet depends on the specific application, at hand.

Solid shank rivets are typically stronger compared to rivets but they require access from both sides of the joint. On the hand blind rivets are not as strong as solid shank rivets but have the advantage of being installed from just one side. It’s important to consider the size of the rivet well. The diameter of the rivet should be slightly larger than the hole diameter to ensure a fit.

Properly installing rivets is crucial for ensuring safety and structural integrity in aircraft construction.

Here are the basic steps for installing a shank rivet:

- Begin by drilling a hole through both pieces of metal that need to be joined.

- Insert the rivet into the hole.

- Place a bucking bar on top of the head of the rivet.

- Use a rivet gun or squeezer to hammer or squeeze the shank of the rivet creating a head on the opposite side.

Here are the basic steps for installing a pop rivet:

- Start by drilling a hole through both pieces of metal that need to be joined.

- Insert the pop rivet into this hole.

- Position your Rivet gun on top of its stem.

- To properly secure a rivet you need to operate the rivet gun by pulling its trigger. This action will pull the stem. Crimp the rivet shank resulting in a head forming on the opposite side.

When working with rivets it is crucial to prioritize safety. Make sure to wear safety glasses as there is a risk of rivets getting dislodged during installation, which could pose harm to your face and eyes.

In conclusion having the skill to perform riveting is vital for aircraft structures technicians. It enables them to contribute towards ensuring aircraft safety and airworthiness by understanding types of rivets and their correct installation techniques.